伦敦,这个世界范围内最有吸引力的帝都,说起来,常常会让人联想到福尔摩斯,贝克街,以及用昏黄灯光照亮贝克街的铸铁灯,案发庄园的铸铁大门等等。铸铁和伦敦有说不清道不明的渊源,它是这个城市的一部分。铸铁作为极为普通的材料,常见于城市街道上的灯柱,栏杆扶手等地。在这个项目中,来自伦敦的6a architects x Paul Smith将铸铁这一极为平实的材料运用得让人刮目相看,铸铁成为了一个高级购物店的时尚门面,十分艺术而风骚的吸引着路人。建筑形象在与周遭和谐的同时也解脱了沉闷的束缚,展现出非同一般的品质。

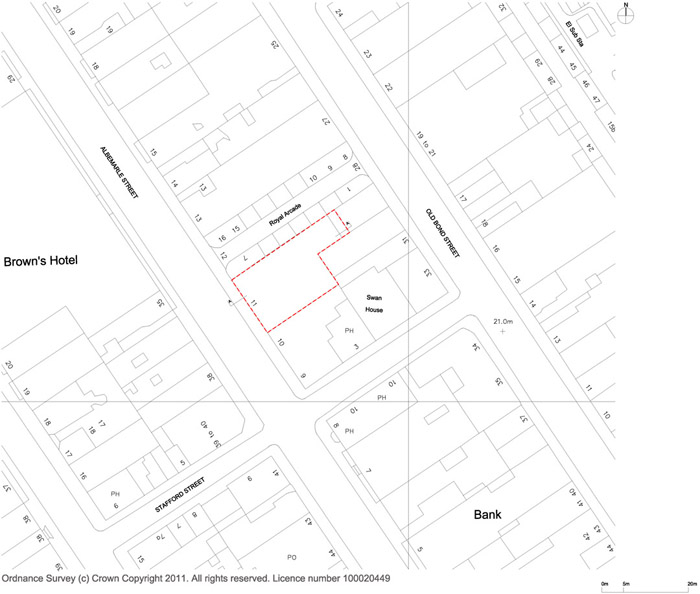

The new Albemarle Street shop front for Paul Smith builds on a familiar material tradition in London. Cast iron forms an understated background to the city’s streets; its railings, gratings, balconies, and lamp posts. Paul’s brief was an eclectic collection of references, images, textures and traditions, encompassing military medals, woven hats and finely drawn gold ingots alongside sharp tailoring, the soft fall of cloth, craftsmanship and delight in surprise. How these disparate influences might find the restraint needed to engage with the neighbourhood at the same time as contributing to its future identity was key, in doing so offering a rare resistance to the increasingly homogenous global high street.

街上的建筑如同联排别墅般紧密的排列,带有美丽几何花纹的铸铁面板爬满了一栋楼的表面,其复杂而深浅不一的编织肌理上演着光与影的戏剧。三重奏的韵律拉响凹凸变化,起伏有致的乐章。黑色低调的铸铁质感搭配莹亮通透的弧形玻璃,橱窗成为明珠。橡木暗门(逃生门)与铸铁立面保持齐平,并与之突出的花纹对应,有着内陷的雕刻肌理。大门外的台阶也是铸铁铺就,随着时间的流逝,台阶将被往来的顾客踩亮,留下时间的痕迹,记录建筑的过往。

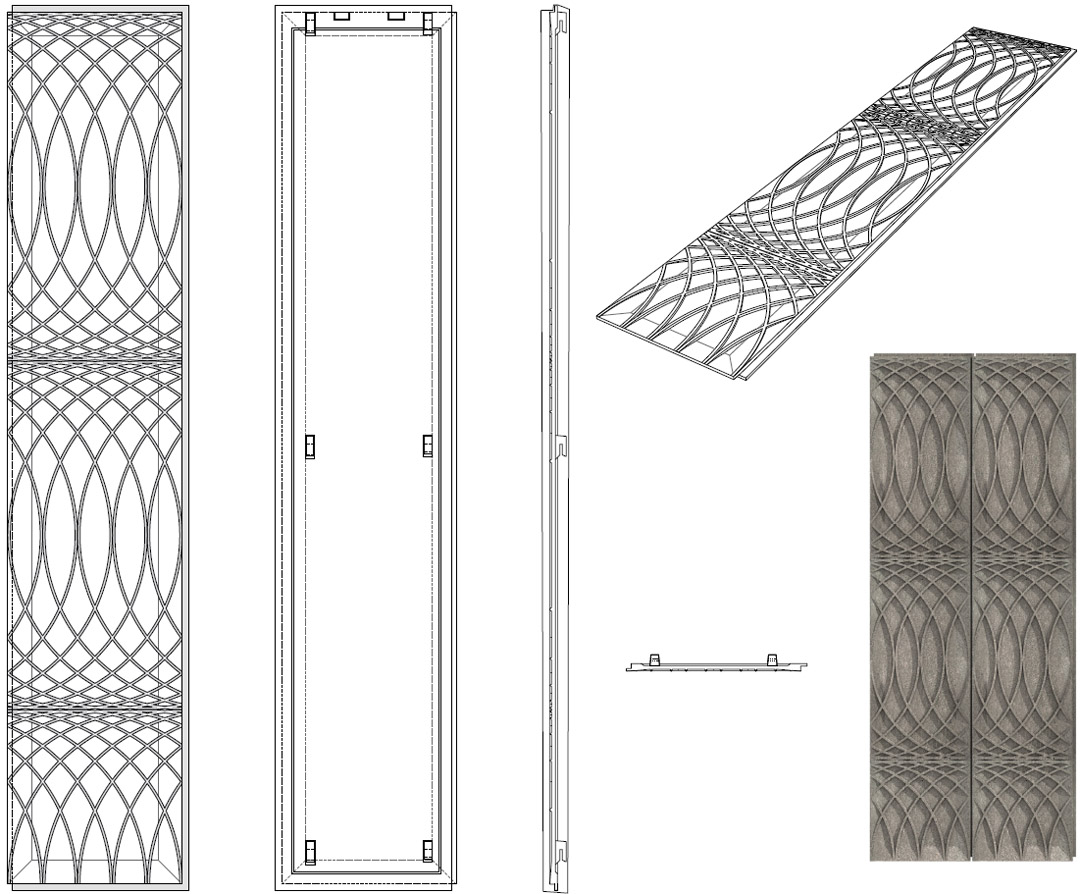

The ground floor rustication of Georgian townhouses and the ornamental language of 18th century shop fronts were reinterpreted and

abstracted in a sinuous pattern of interlocking circles cast into a new solid iron fa?ade. The repetition of the typical Regency shape brought an optical complexity which, with the play of sunlight and shadow, turns the pattern into a deep surface texture. Seen obliquely it seems woven, like a fine cloth.

The surface is further enlivened by the latent makers’ marks of the casting process and the natural patination of the cast iron. A more intimate discovery is to be made in the trio of small drawings by Paul cast directly into panels scattered across the fa?ade.

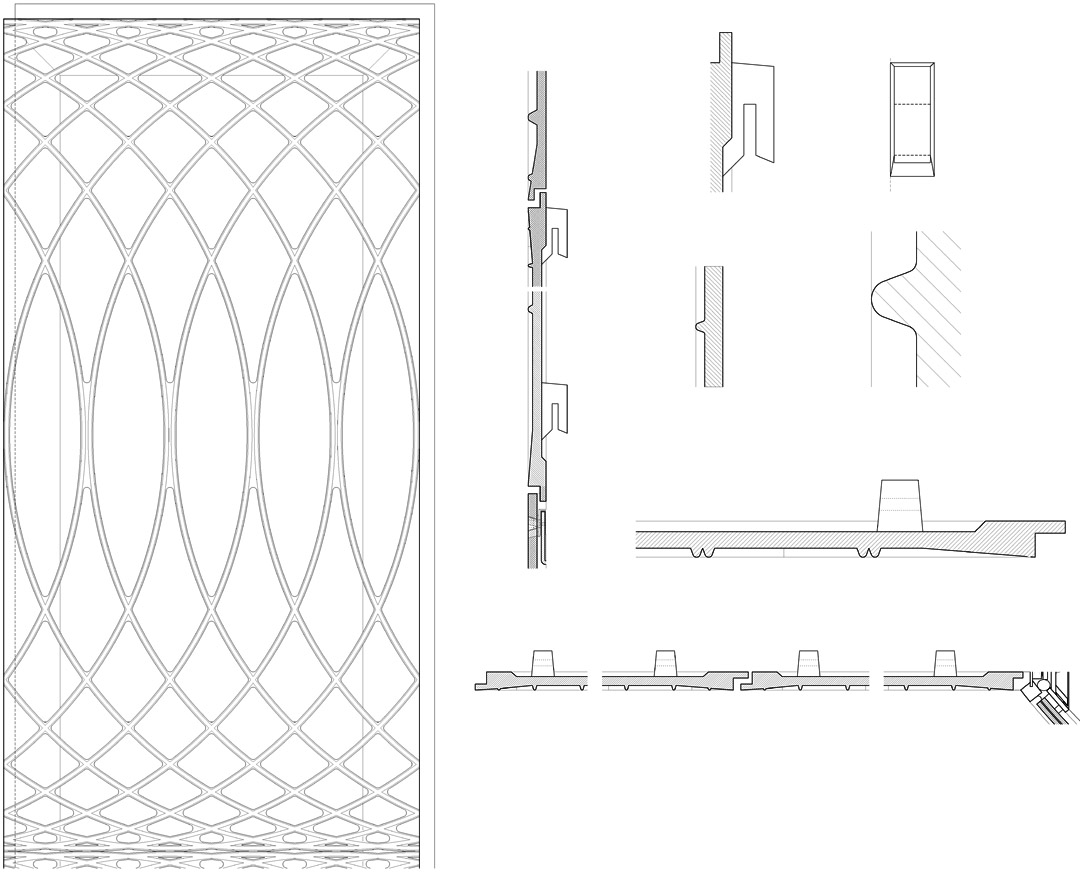

Curved windows project from the darkly textured iron as luminous vitrines, with a nod to the curved glass of the nearby arcades. A secret door of stained oak lies flush with the cast iron panels: the inverted carving of the timber recalls the mould and sand bed prepared for the molten metal.

The cast iron panels curve in to the recessed oak entrance door, a gently bowed iron step evokes worn away treads. Over time, the iron threshold will polish under foot, recording the life of the building in its material.

Technical Detail:

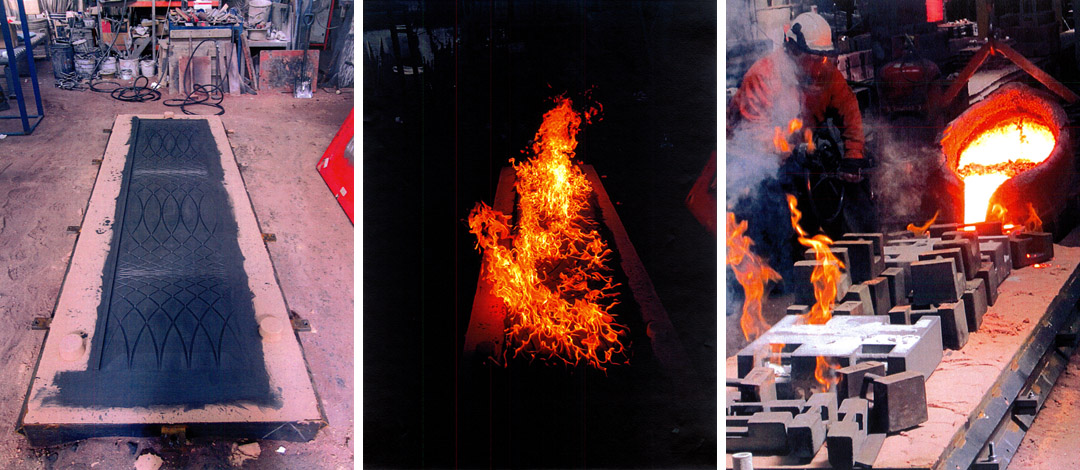

Each cast iron panel type was digitally modelled and the patterns CNC carved from blocks of dense Polyurethane. The patterns were then used to form traditional sand casting moulds in the foundry. The panels were sand cast in Spheroidal Graphite Iron (SGI), then allowed to rust. Once the orange Iron Oxide coating had formed on the surface of the panels, Hammerite Kurust was applied to the surface of the iron, forming a rich black patina of Iron Tannate. An additional coating of Hammerite Paint was applied to the back of the panels to ensure additional longevity.

Hooks were cast into the back of the panels to allow them to be hung directly onto Halfen horizontal Stainless Steel cladding rails. Each of the panels incorporates a series of lap joints to conceal the cladding substructure whilst allowing for thermal expansion and ventilation.

The curved windows are entirely bespoke fabrications, incorporating a laser cut galvanised steel plate primary structure, a stainless steel carrier frame to which the curved glass is structurally bonded and a weather tight brass shroud. The windows are thermally broken using continuous nylon blocks. The windows are designed so that the glass units can be replaced without structurally bonding the glass on site. The curved glass was bent to extremely fine tolerances in Barcelona by Cricursa and structurally bonded to the stainless steel subframe in the UK.

The fire escape door to the offices above is set flush with the surface of the cast iron, and the inverse of the circular pattern CNC carved into the solid oak boards. A language of joinery drip details provides a final level of embellishment, and the oak is finished with a dark oil to match the surrounding iron. The main entrance door is also fabricated in oiled oak, and the glass is flush silicon bonded into the frame.

Design Team:

6a architects and Paul Smith

Montresor Partnership: Fa?ade Specialist

KMB: Project Manager

Rodgers Leask: Structural Engineer

Contractors/ Suppliers:

Main Contractor: Rise Contracts

Foundry: FSE

CNC: Data2Pattern

Bespoke Metalwork: Harrington Fabrications

Curved Glass: Cricursa

Joinery: SV Joinery

Glazing: Saper Glass

Photographer: 6a Architects/ DG: David Grandorge

文章来源: 6a architects x Paul Smith